Are you wondering:

✔ ERW vs seamless pipe comparison

✔ Which is better: ERW steel pipe or seamless steel pipe?

✔ Applications of ERW steel pipe and seamless pipes

✔ Cost difference ERW seamless pipe

Understanding the Fundamental Differences

1. Manufacturing Process

ERW (Electric Resistance Welded) Pipes:

Made by rolling steel coils and welding the seam electrically

More cost-effective for medium/low-pressure applications

Ideal for: water pipelines, fencing, structural uses

Seamless Pipes:

Created by piercing solid steel billets (no welding)

Superior for high-pressure/temperature services

Essential for: oil & gas, power plants, chemical industries

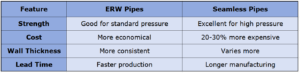

2. Key Comparison

Xinyue Steel Group: Your Complete Pipe Solution Provider

As a leading Chinese manufacturer (www.xysteelpipe.com), we supply both ERW and seamless pipes to meet all project requirements:

For ERW Pipes:

Range: 1/2″ to 24″ diameters

Standards: API 5L, ASTM A53, EN 10219

Recent project: Supplied 5,000 tons for African water infrastructure

For Seamless Pipes:

Range: 1/8″ to 24″ diameters

Grades: ASTM A106, API 5L, ASTM A335

Application: High-pressure gas pipelines in Middle East

Why Choose Xinyue?

✅ One-stop shop for all pipe types

✅ Competitive pricing with direct factory access

✅ Quality assurance: Full MTC and third-party inspection available

Whether your project needs cost-effective ERW pipes or high-performance seamless pipes, Xinyue Steel Group has the expertise and capacity to deliver.

Contact us today for technical advice and quotes!

Written by Xinyue Steel Team

Xinyue Contact Details:

Email: sales@xysteelpipe.com

WhatsApp: 086 189 7484 9825

Website: www.xysteelpipe.com