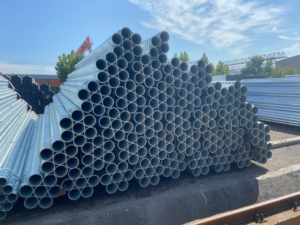

Carbon steel pipe and stainless steel pipe are two commonly used types of pipes in the industrial and commercial sectors. Although both are made of steel, there are significant differences between the two that affect their performance, reliability, and overall quality. In this article, Xinyue Steel will take a closer look at the differences between carbon steel pipes and stainless steel pipes, including their composition, corrosion resistance, cost, and other important factors.

—Steel Pipe’s Composition

The primary difference between carbon steel pipes and stainless steel pipes is their composition. Carbon steel pipes are made from iron and carbon, with trace amounts of other elements such as manganese, silicon, and sulfur. Carbon steel pipes are commonly used in the construction and oil and gas industries due to their low cost and high strength. Stainless steel pipes, on the other hand, are made from a mixture of iron, carbon, and chromium. Chromium is added to the mixture to provide increased corrosion resistance, which is a key advantage of stainless steel over carbon steel. Additionally, other elements such as nickel, molybdenum, and nitrogen may be added to enhance the performance of stainless steel pipes in specific applications.

—Steel Pipe’s Corrosion Resistance

One of the most significant advantages of stainless steel pipes over carbon steel pipes is their increased resistance to corrosion. Carbon steel pipes are highly susceptible to rust and corrosion, which can lead to leaks and other types of damage over time. Stainless steel pipes, on the other hand, have a much higher resistance to corrosion due to the presence of chromium in the material. Chromium forms a protective layer on the surface of the pipe, which prevents corrosion and rust from developing. This makes stainless steel pipes an ideal choice for use in corrosive environments and in applications that require high levels of sanitation.

—Steel Pipe’s Cost

Cost is another important factor to consider when selecting between carbon steel pipes and stainless steel pipes. Carbon steel pipes are typically less expensive than stainless steel pipes due to their simpler composition and lower production costs. However, the lower cost of carbon steel pipes can come at a cost in terms of durability and corrosion resistance. Stainless steel pipes are more expensive, but they offer higher quality and performance. The investment in a stainless steel pipe is often worth it, given the increased resistance to corrosion and the longer lifespan of the final product.

—Steel Pipe’s Applications

Another important difference between carbon steel pipes and stainless steel pipes is the types of applications they are best suited for. Carbon steel pipes are ideal for use in construction, oil and gas, and other applications that require high levels of strength and durability. Stainless steel pipes are ideal for use in applications that require high levels of sanitation and corrosion resistance. They are commonly used in food and beverage processing, pharmaceutical manufacturing, and other applications where cleanliness and durability are critical.

In conclusion, carbon steel pipes and stainless steel pipes are two commonly used types of pipes in the industrial and commercial sectors. Although both are made of steel, there are significant differences between the two, including their composition, corrosion resistance, cost, and applications. Understanding these differences is important when selecting the right type of pipe for your application. Ultimately, the best choice depends on your specific needs, requirements, and budget.

For both stainless steel pipe and carbon steel pipe, Xinyue Steel Group is always your best choice for steel pipe supplier!