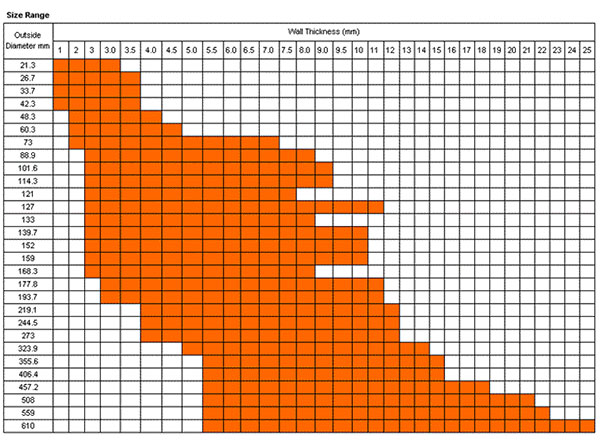

Specification

ERW Steel Pipe

Electric Resistance Welded Steel Pipe

Usage: Used for low pressure liquid delivery, such as water, gas, and oil. Oil drilling and machinery manufacturing, etc.

Process:

ERW : Electric Resistance Welded pipe

HFI: High Frequency Induction weld pipe

EFW: Electric Fusion Welded Pipe

Standard: API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Steel Grade:

API 5L : GR B, X42,X46, X56, X60,X65,X70

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360- L555

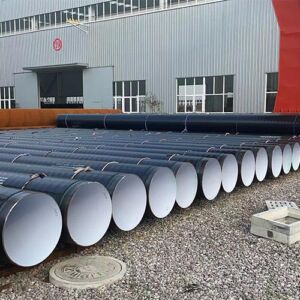

Surface: Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204/3.1B

Wall Thickness

API 5L Line Pipe

STEEL GRADE

API 5L PSL1/PSL2 GR B , X42, X46, X52, X60, X65, X70

STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

% by mass, Maximum |

||||

|

C |

Si |

Mn |

P |

S |

|

|

GR B |

0.26 |

0.40 |

1.20 |

0.030 |

0.030 |

|

X42 |

0.26 |

0.40 |

1.30 |

0.030 |

0.030 |

|

X46 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X52 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X56 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X60 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X65 |

0.26 |

0.40 |

1.45 |

0.030 |

0.030 |

|

X70 |

0.26 |

0.40 |

1.65 |

0.030 |

0.030 |

MECHANICAL PROPERTIES

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min.% |

|

GR B |

245 |

415 |

|

|

X42 |

290 |

415 |

|

|

X46 |

320 |

435 |

|

|

X52 |

360 |

460 |

|

|

X56 |

390 |

490 |

|

|

X60 |

415 |

520 |

|

|

X65 |

450 |

535 |

|

|

X70 |

485 |

570 |

TEST REQUIRED

Chemical Analysis, Mechanical Test, Visusal Inspection , Tension Test, Dimension Check

Bend Test , Flattenting Test, Impact Test, DWT Test, NDT Test

Hydrostatic Test, Hardness Test…..

ASTM A53 GR B Data Sheet

STEEL CHEMICAL COMPOSITION

The steel shall conform to the following requirements as to chemical composition:

|

STEEL GRADE |

Composition Max, % |

||||||||

|

C |

Mn |

P |

S |

Cu |

Ni |

Cr |

Mo |

V |

|

|

GR B |

0.30 |

1.20 |

0.05 |

0.05 |

0.40 |

0.40 |

0.40 |

0.15 |

0.08 |

MECHANICAL PROPERTIES

|

STEEL GRADE |

Tensile Strength ,min, Psi ( MPA) |

Yield Strength , min, psi, ( MPA) |

|

GR B |

60 000 (415) |

350 000 (240) |