Localización del proyecto:GERMANY

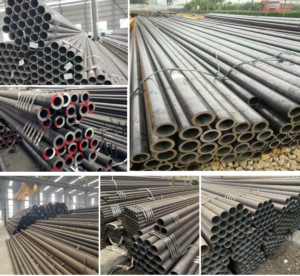

Producto:alloy seamless steel pipe

Localización del proyecto: ASMESA335, Grado P22, ASME II/A latest Edition

Localización del proyecto: 457*23.8mm with different length

Solicitud:High temperature blast furnace

Localización del proyecto:2022.06.01

Localización del proyecto:2022.08.03

Localización del proyecto:2022.10.03

niki:2022.11.30

El cliente descrito es un cliente alemán que es un comerciante global.. Ha cooperado con Xinyue durante 5 years and is our very important partner. Por supuesto, because of the nature of the customer, he has many suppliers. Then why did Xinyue stand out from the crowd. This is inseparable from the very professional service of our business manager Curtis. Over the past five years, he has been able to provide very professional services and opinions for every inquiry of customers, and to provide customers with the best quality products for every transaction order.

A principios de este año, there was a order of stainless steel plates. Because of the large price difference, the customer finally chose other suppliers. Sin embargo, Curtis analyzed the unreasonable price for the customer from its professional perspective at that time, but the final customer still gave it to someone else. Como se esperaba, the product of that order was unqualified and a lawsuit was brought. En el presente, Xinyue is also actively helping customers to deal with their problems and strive to cover their losses. Our business attitude makes the customer very satisfied, and the boss of this customer said that the subsequent purchase orders of their company should be confirmed with Curtis at the first time. If Xinyue can do it, we are the only choice. I think this is also the best feedback for us to keep our original intention

This batch of order is made of alloy seamless pipes, with a weight of 42 tons and a specification of 457 * 23.8. Sin embargo, the difficulty of this order is that the length is different, and the length of each pipe is from 1.2 to 8.5m. And there are high strict technical requirements: – 27 grado de impacto, Per batch, 3x simulating PWHT of sample pieces with diagram,Surface inside and outside, clean SA 2.5 (rust and scale free), Normalized at 920 ° C & at least 70 min and tempered at 730 ° C for at least 110 min,Hydrostatic test 118bar is to be used, holding time 20 sec, Documentation / acceptance test certificate 3.2 according to DIN 10204. After the studying of our technical team, we can finally meet all the requirements of customers. This batch of orders is now in production, and we look forward to perfect delivery.

Escrito por Elena